PM Technologies

"Creative Engineering with new Technology"

"With Creativity, Engineering and new Technology we strife to be always one step ahead"

the goal is to get it done!

Introduction

The company was founded on the principal of providing Asian production services to customers all over the world.

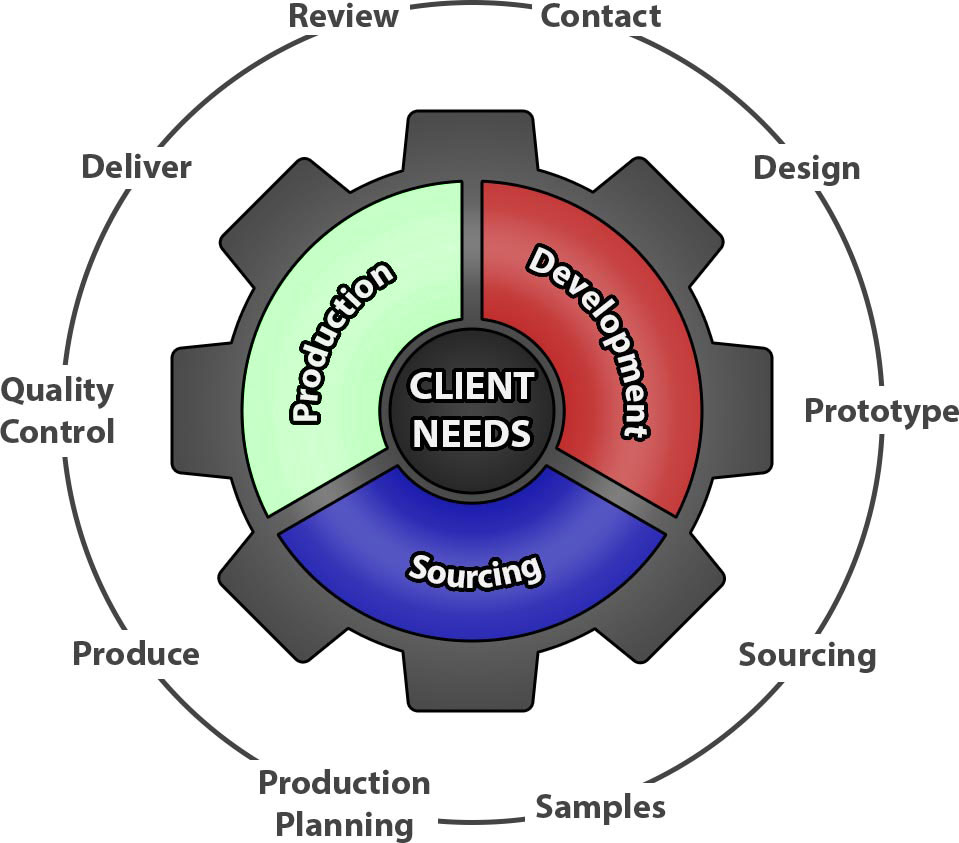

Our primary business method of operations is provided a combination of services that can best support the needs of our customers/partners that want to take advantage of low cost production in Asia but do not have the resources to manage programs in person. The services are selected based on the customers requirements, additional services can be added at any time to support the program needs. Once the services have been identified we will assign a supporting staff and make the introductions to the team.

We can qualify the suppliers for our customers based on our experience or work with your approved supplier. All purchase orders are paid direct to the supplier, we are NOT a trading company.

Capabilities

In cooperation with your and our team we can decide which services fit your needs. Based on product and team there will be always a custom solution available.

Centralized purchase

Even though we don’t buy the tools and parts ourselves, we can act as an extended arm of the purchaser here in China and bargain better prices by using the combined purchase value of all customers as leverage. This way even smaller customers and projects will get taken as serious as bigger ones by suppliers. Our team on site, can evaluate the capacity and financial stability and take this valuable information into account during the final bargaining stage and provide the best quotations for all customers.

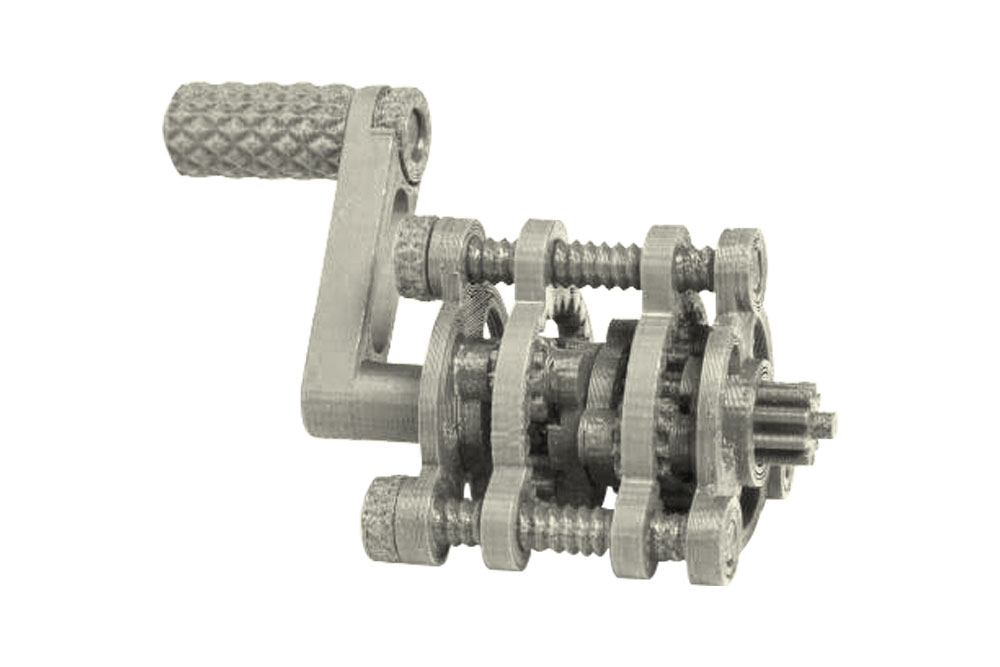

Product design and prototyping

We design and analyze a product theoretically based on function, production-efficiency and other demand. As a second step, we can build prototype parts in varied difference material to simulate function and assembly.

- State-of-the-art 3D printing

- Prototype molding

- Assembly- and factual test for prototypes

- Goniophotometer

- 3D scanning for reverse engineering

- All processes and project can be integrated to customers and suppliers without delay

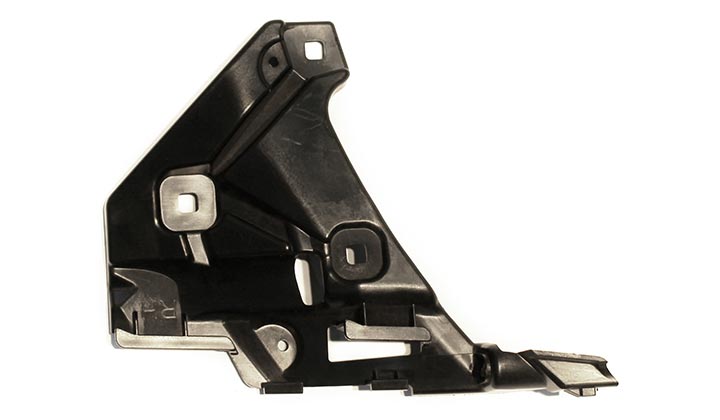

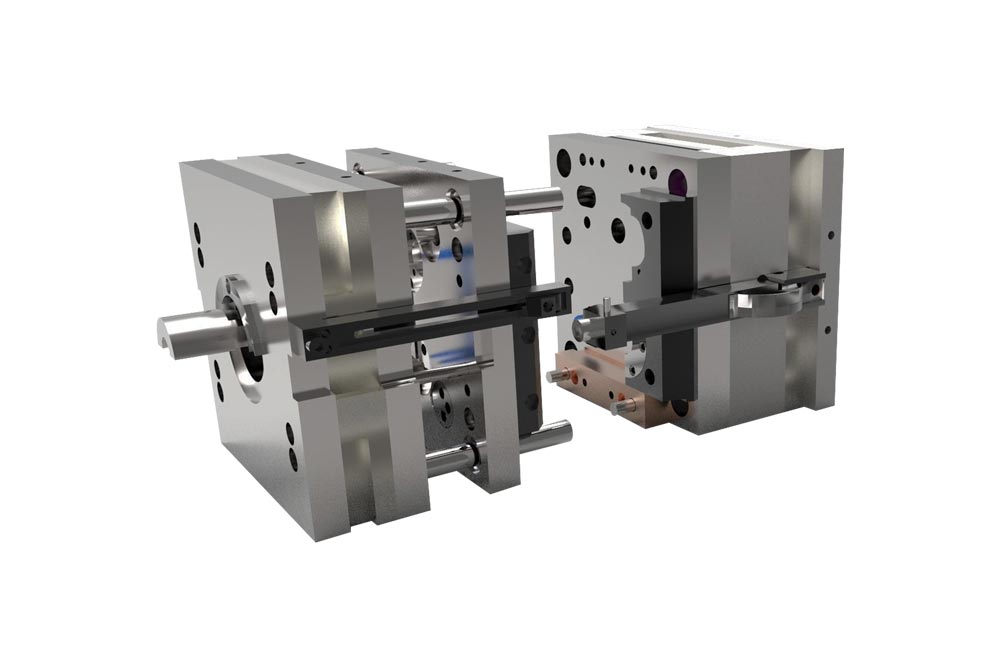

Export Molds: Tooling design, tool production and shipment

In case the mold will be integrated to the production in a different factory and country, the local standards need to be implemented very carefully in the design to guaranty a smooth production start within the demanded cycle time and quality demands.

- Mold flow

- DFM’s

- Mold designs in 3D

- CPK trial run

- Pilot production run

- Detailed mold inspection and report

- Online management software

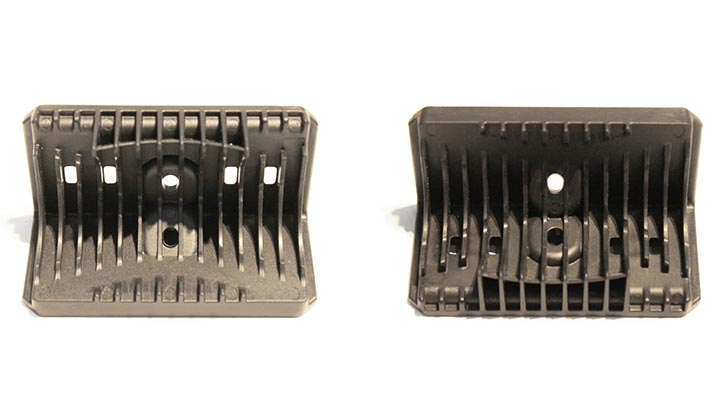

Injection molding / Production support

The work starts with the control of the quality and time schedule of the molds, over trials, adjustments to pilot runs and mass production. Our advanced project management is integrated to suppliers and customers.

- Over tens of millions of parts and 400 molds produced in China per year. 98.6% on time delivery

- Improve production stability, reduce scrap rate

- Improve production efficiency, reduce cycle time

- Improve packaging layout and implementation into the production line

- Automation of production lines

Logistics and warehousing

Our logistics and warehouse team in Hong Kong can provide warehouse space and organize shipments by; sea, air,train, truck and express. With the growing amount of shipments, we can provide lower costs for the logistics demand of our customers.

- Deliveries to more than 100 countries worldwide

- Just-in-time and safety stocking programs offered

- Air/Sea and Land

- Train shipments from Asia to Europe

- Ex -/ Import support

Reverse Engineering

With the growing demand for difficult parts we have built up a high-end QC department. We can quickly find out what we need to improve on the injection machine and what can be improved in the part- and tool design.

- State-of-the-art 3D scanning

- Scientific molding

- Best Fit comparison – see 3D deviations between model and produced product

- Recreate Solid 3D files based on real objects

- Tactile and optical measurement methods

LSR - Liquid Silicon Rubber

LSR as a material provides many new options for product designs. We have worked with LSR in the past years and developed manufacturing systems to process LSR without material waste and shorter cycle times.

- Cold runner systems with needle valves

- Reduce cycle time

- Reduce waste

Risk Management / Recovery of Production

All companies can face trouble with suppliers. We have helped customers in the past with relocating production.

- IP rights

- Locating production facilities and their owners

- Suppliers with financial problems

- Uncooperative or incapable suppliers

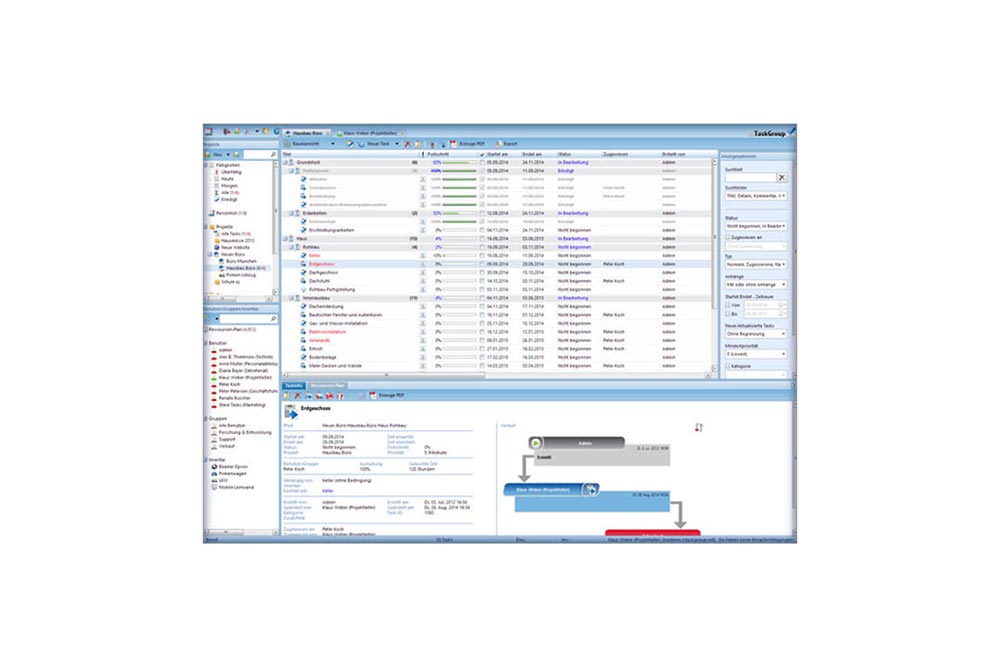

Online Project Management Software

With our projects management system, your projects are secure and accessible from your computer or mobile phone 24/7.

- See mile stones

- Real-time updates

- See time plans

- Latest report

- Reduce long email chains

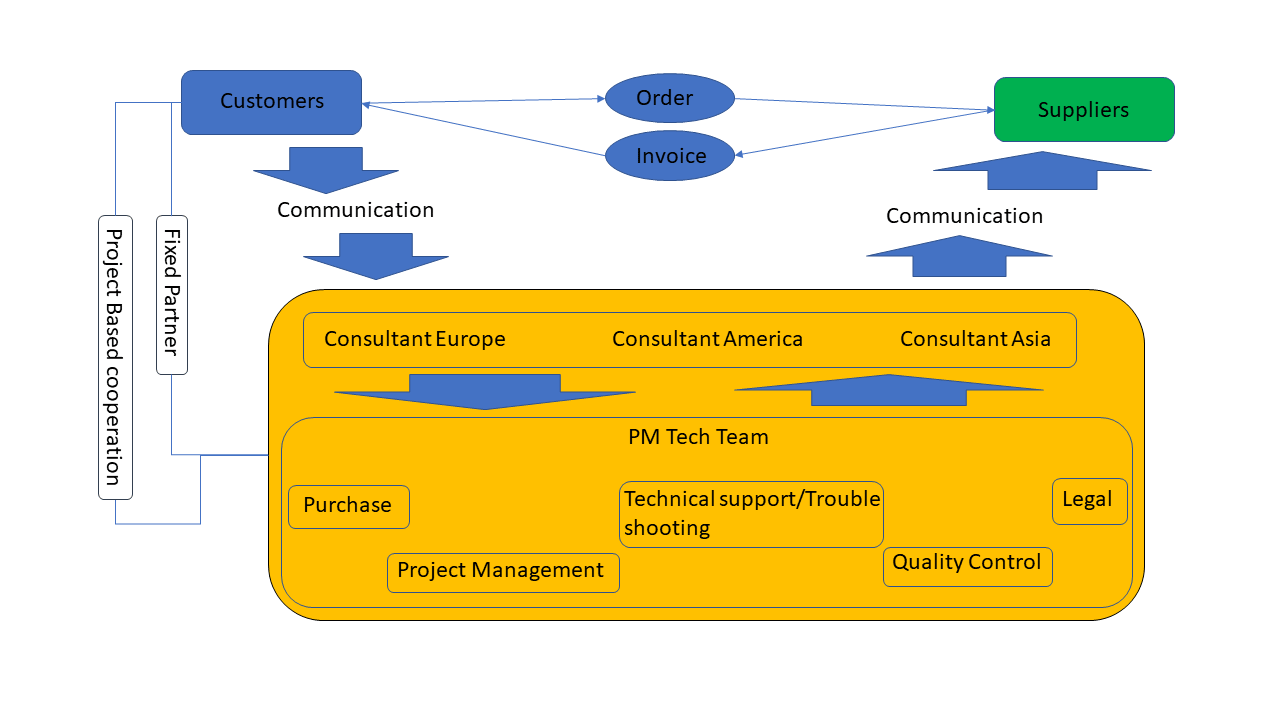

Organization Chart

Portfolio

- Featured

- Automotive - 1

- Automotive - 3

- Construction

- Designer Furniture

- LSR- Liquid Silicone Rubber

Management Team

Shirley Xie

Office Manager Shenzhen

Risto Kalliainen

Owner Finland

Tobias Koenings

Managing Director

Petri Mikkola – Founder

„I started the company to provide service for customers in Asian countries and find real added value for the manufacturing chain. We wanted to face the challenge of communication, knowledge and new technology head-on here onsite. With local and western personnel, we can ensure a success for customer projects and production from early stage R&D to deliveries for customer where ever it is needed. Our advantage is that we offer a service for whole delivery chain without trading but with professional people.

We have a very stable customer base and have continuously grown with them facing changing challenges. We can truly say that to make a successful business we work on our customer’s goals.“

Get In Touch

Head Office Shenzhen

PM TECH (SHENZHEN) LTD.

Tel: +86-755-8827-8081

Address: #606, Building 4, Fantasia Mic International Plaza, NanHai Avenue, Nan Shan, Shenzhen, Peoples Republic of China

Address in Chinese: 深圳市南山区南海大道花样年美年广场4栋606

Warehouse HongKong

DELIVERED LTD.

Tel: +852 2110 1204 / +852 2110 1245

Fax: +852 2110 1279

Address: B1 Block A, Sunshine Kowloon Bay Cargo Centre, 59 Tai Yip Street, Kowloon Bay

Hong Kong Office

PM TECHNOLOGY CONSULTING SERVICES LIMITED

E-mail: hkoffice@pm-tcs.com

Address: 3208, 32/F., Central Plaza, 18 Harbor Road, Wanchai, Hong Kong

Copyright © PM Technologies 2019. All rights reserved.